Industrial hydrogen: a 20 MW project in the Netherlands

• The first zero-carbon hydrogen plant on this scale to be implemented in Europe, with a production capacity of 3,000 tons per year (20 MW)

• A project initiated by Nouryon and Gasunie, two leading industrial groups, to be installed in Delfzijl, the Netherlands

• Reducing CO2 emissions by up to 27,000 tons per year, pointing towards the decarbonization of the industry sector

La Motte Fanjas (France), January 22, 2020 – 08:00 am CET – McPhy (Euronext Paris Compartment C: MCPHY, FR0011742329), a specialist in hydrogen production and distribution equipment, today announces it has been selected to equip the largest electrolysis plant for zero-carbon hydrogen production, the first of its kind and on this scale in Europe.

Now is the time to scale-up and industrialize clean hydrogen production technologies to lower their costs and boost the rise of a clean, secure and cost-competitive hydrogen ecosystem.

Laurent Carme, Chief Executive Officer of McPhy, states: “We are proud of the trust we received from Nouryon and Gasunie, two major industrial groups. The size and scope of this unique project, as well as its deep integration into our customers’ processes, represent a major step change for McPhy and more globally for the hydrogen market. Now is the time to scale-up and industrialize clean hydrogen production technologies to lower their costs and boost the rise of a clean, secure and cost-competitive hydrogen ecosystem.”

With the technology from McPhy we are one step closer to competitive large-scale production of green hydrogen.

Marcel Galjee, Energy Director at Nouryon Industrial Chemicals, adds: “Green hydrogen is a cornerstone of building a sustainable, circular economy. Nouryon is already a leader in electrolysis in Europe and with the technology from McPhy we are one step closer to competitive large-scale production of green hydrogen for a more sustainable future.”

The first large-scale zero-carbon hydrogen project to be implemented in Europe

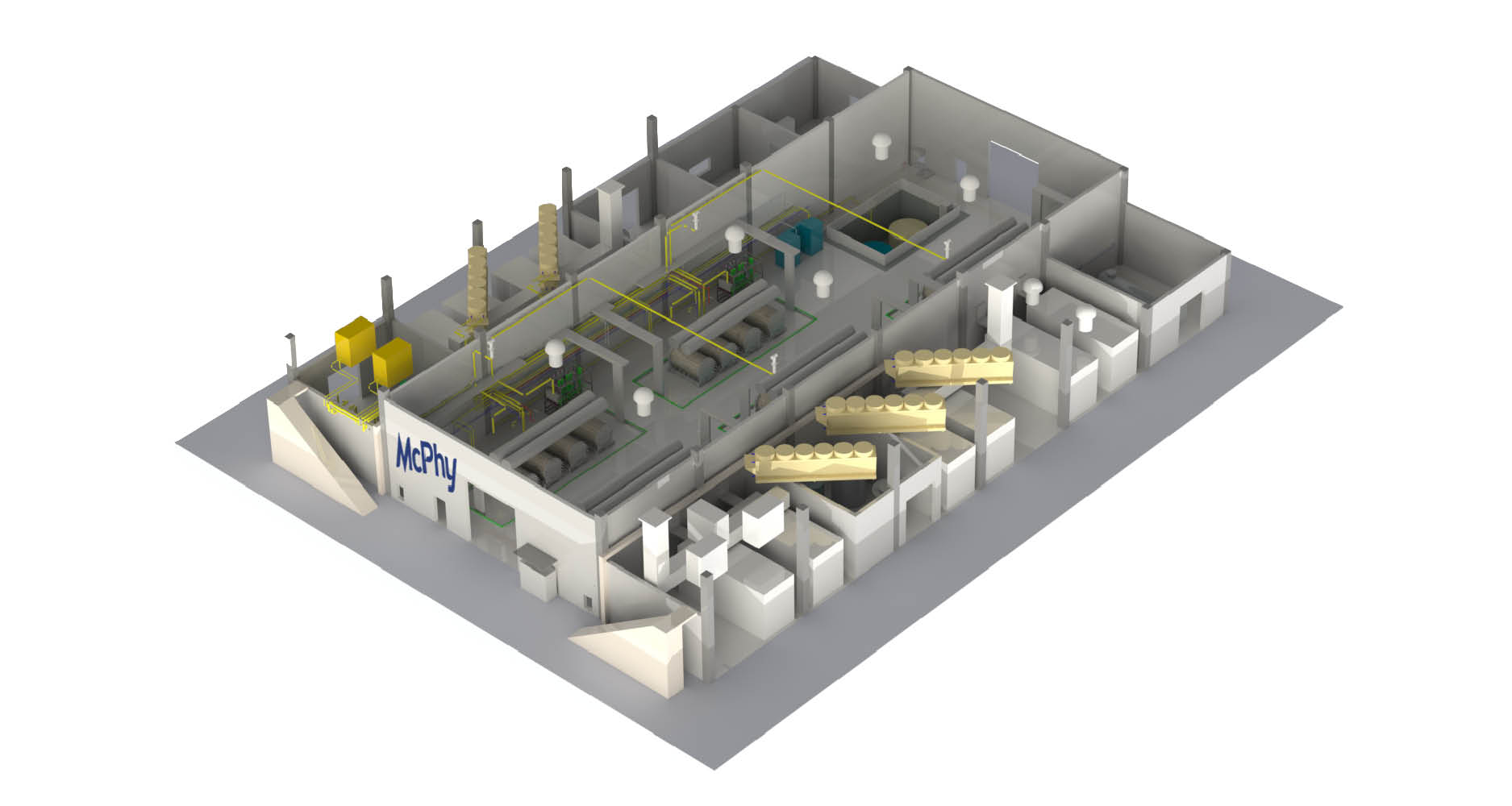

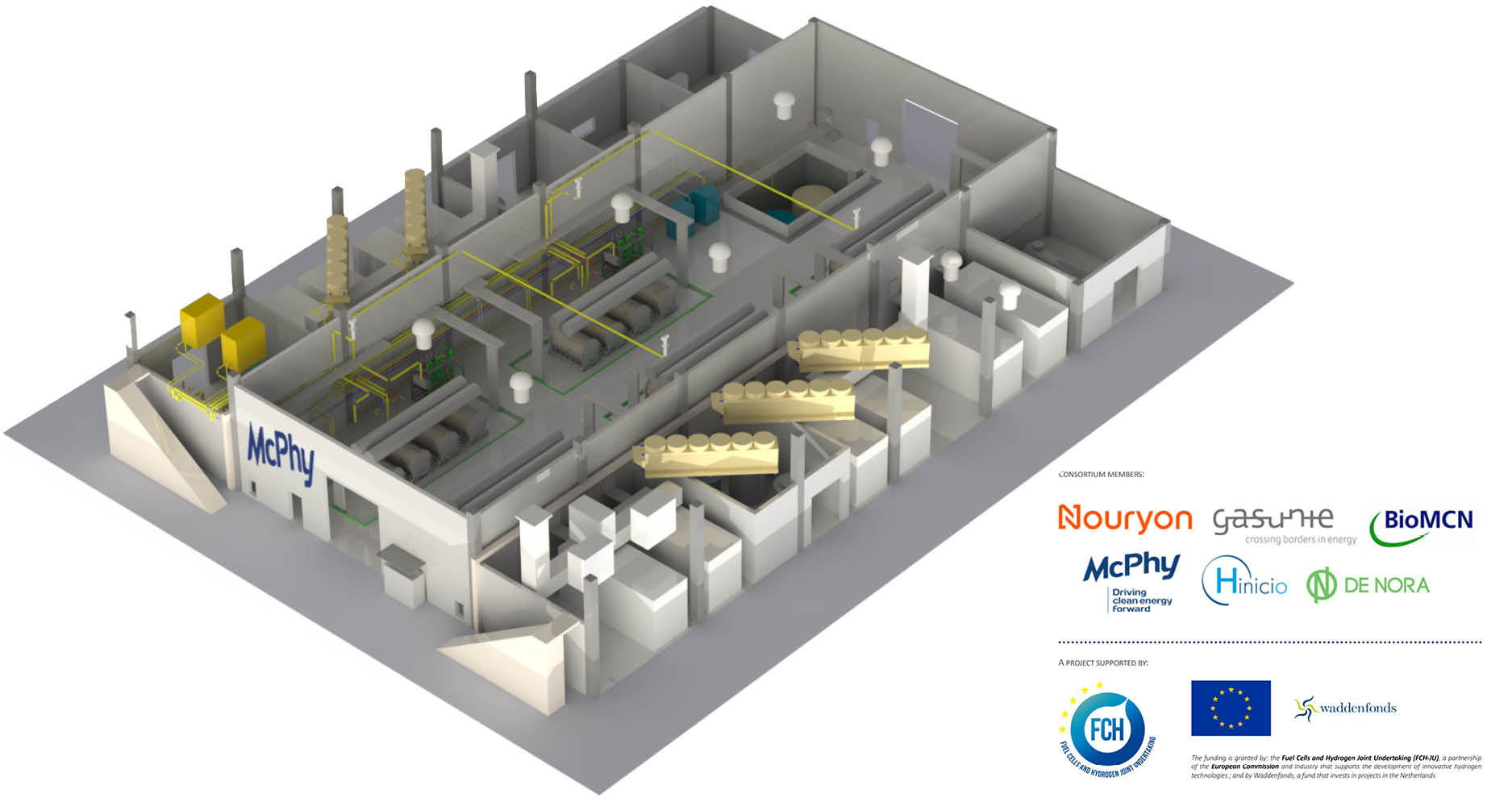

The 20 MW hydrogen production platform will be designed, manufactured and integrated by McPhy with its innovative electrolysis technology “Augmented McLyzer” and will convert green electricity by electrolysis into 3,000 tons of clean hydrogen per year.

This will be used to produce bio methanol and will contribute to reducing CO2 emissions by up to 27,000 tons per year.

This project, initiated by Nouryon, a leading specialty chemical company, and Gasunie, a gas infrastructure company, is a front-runner among hydrogen initiatives with the objective of reducing carbon emissions.

The project’s value chain breaks down as follows:

- Conversion of electricity from renewable sources into zero-carbon hydrogen (by the 20 MW electrolysis platform developed by McPhy);

- Transport of hydrogen from the point of production to the point of consumption;

- Production of clean methanol.

The proposed clean hydrogen project will be funded by an €11m EU grant from the Fuel Cells and Hydrogen Joint Undertaking (FCH-JU) as well as an additional €5m in subsidies from Waddenfonds, a fund that invests in projects in the Netherlands.

McPhy, a technological breakthrough allowing hydrogen to transition to an industrial scale

This reflects our constant innovation policy as well as our expertise in large-scale platforms electrolysis.

Following a technological review conducted by Nouryon, the innovative electrolysis technology “Augmented McLyzer” by McPhy has been selected to be the cornerstone of this key project.

“This reflects our constant innovation policy as well as our expertise in large-scale platforms electrolysis. Our electrolysis platform will produce zero-carbon hydrogen with best-in class performances. This project confirms the relevance of our technological positioning and our transition to an industrial scale, in order to better meet the future needs of the industry as well as the mobility and energy sectors”, concludes Laurent Carme.

The “Augmented McLyzer” technology consists of a unique combination of McPhy 30-bar high-pressure alkaline electrolysis and a package of advanced electrodes, specifically designed for large-scale platforms (multi-MW).

It is currently the most mature and robust technology available on the market, recognized among the market leaders and one of the most promising in terms of future development.

McPhy will be involved in the pre-engineering phase and subsequently in the detailed engineering, production and commissioning of the electrolysis platform.

Upcoming financial communication

2019 annual revenues: Tuesday January 28, 2020, after market.

About McPhy

In the framework of the energy transition, and as a leading supplier of hydrogen production, storage and distribution equipment, McPhy contributes to the deployment of clean hydrogen throughout the world.

Thanks to its wide range of products and services dedicated to the hydrogen energy, zero emission mobility and industrial hydrogen markets, McPhy provides turnkey solutions to its clients. These solutions are tailored to our client applications: renewable energy surplus storage and valorization, fuel cell car refueling, raw material for industrial sites.

As a designer, manufacturer and integrator of hydrogen equipment since 2008, McPhy has three development, engineering and production units based in Europe (France, Italy, Germany).

The company’s international subsidiaries ensure a global sales coverage of McPhy’s innovative hydrogen solutions.

McPhy is listed on NYSE Euronext Paris (Segment C, ISIN code: FR0011742329; ticker: MCPHY).

Media relations

NewCap

Nicolas Merigeau

T. +33 (0)1 44 71 94 98

mcphy@newcap.fr

Investor relations

NewCap

Julie Coulot | Emmanuel Huynh

T. +33 (0)1 44 71 20 40

mcphy@newcap.fr

About Nouryon

We are a global specialty chemicals leader. Markets worldwide rely on our essential chemistry in the manufacture of everyday products such as paper, plastics, building materials, food, pharmaceuticals, and personal care items. Building on our nearly 400-year history, the dedication of our 10,000 employees, and our shared commitment to business growth, strong financial performance, safety, sustainability, and innovation, we have established a world-class business and built strong partnerships with our customers. We operate in over 80 countries around the world and our portfolio of industry-leading brands includes Eka, Dissolvine, Trigonox, and Berol.

About Gasunie

Gasunie is a European gas infrastructure company. Gasunie’s network is one of the largest high-pressure pipeline networks in Europe, comprising over 15,000 kilometres of pipeline in the Netherlands and northern Germany. Gasunie wants to help accelerate the transition to a CO2-neutral energy supply and believes that gas-related innovations, for instance in the form of renewable gases such as hydrogen and green gas, can make an important contribution. Both existing and new gas infrastructure play a key role here.

About the Fuel Cells and Hydrogen Joint Undertaking (FCH-JU)

The Fuel Cells and Hydrogen Joint Undertaking (FCH JU) is a unique partnership between the European Commission and the industry to fund and support the development of hydrogen technologies including research, technological development and demonstration (RTD) activities in fuel cell and hydrogen energy technologies in Europe. Its aim is to accelerate the market introduction of these technologies, realizing their potential as an instrument in achieving a carbon-clean energy system.

The three members of the FCH JU are the European Commission, fuel cell and hydrogen industries represented by Hydrogen Europe and the research community represented by Hydrogen Europe Research.